Background

In the midst of the 2022-23 season, our Formula SAE team made a choice to move away from our historic cylindrical cell battery design in favor of a pouch-cell based pack. This season, Carnegie Mellon Racing drove under the power of a pouch-cell battery pack for the first time in history. This is what’s inside.

— PROJECT NAME —

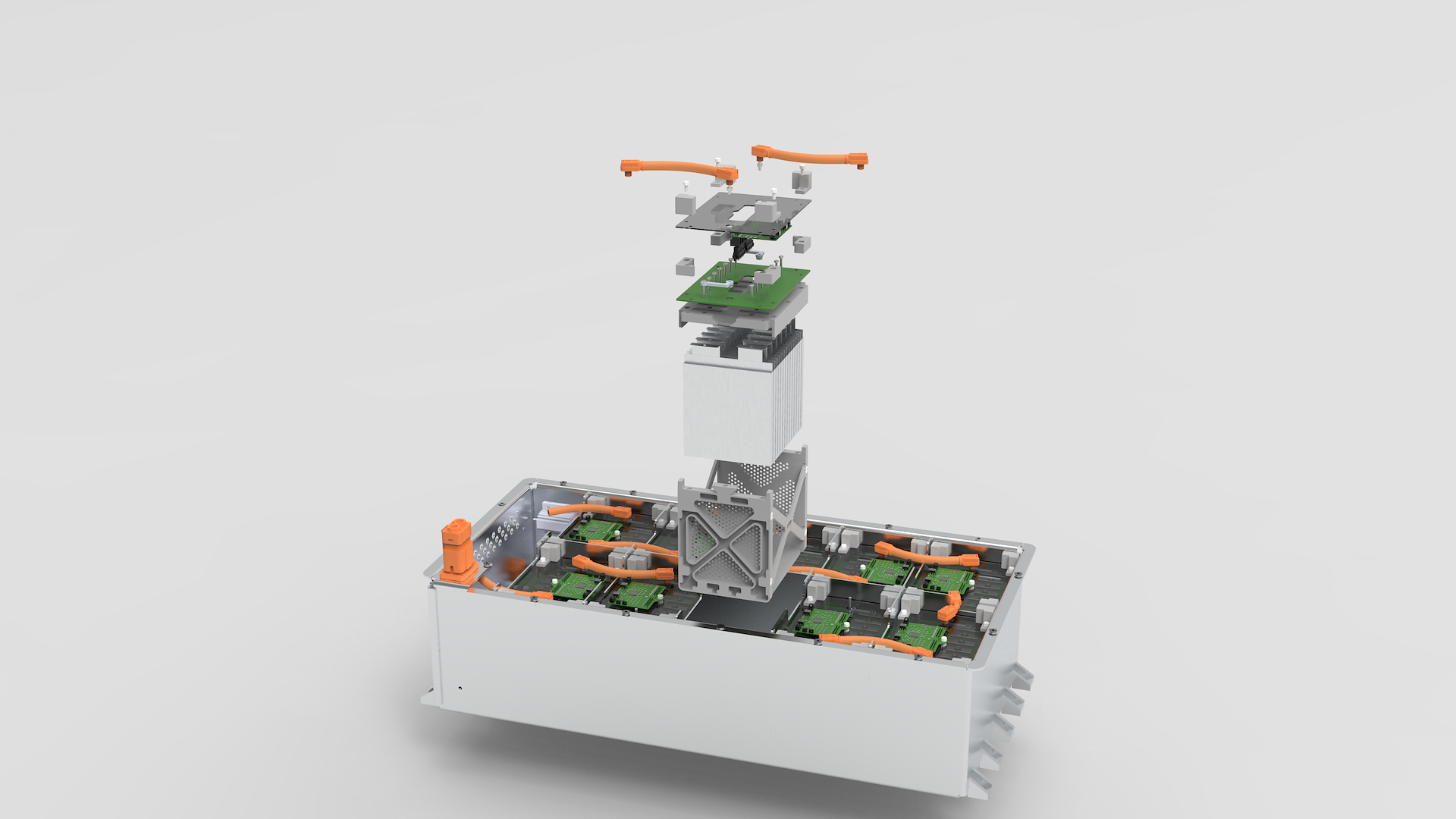

EV Pouch Cell Battery Module

— APPLICATION —

CMR "24e" FSAE EV Racecar

— ACHIEVEMENTS—

Formula H+E 44km Endurance

FSAE Michigan 22km Endurance

Garrett Powertrain Innovation Award

General Specs:

Mass – 10.0 lbs

Cost – $95/module (excluding cells)

Cell – COSMX CA95B0D0HD 13Ah x14

Voltage at 100% SOC – 60V

Module Configuration – 14s1p

Full Pack Specs (x10 Modules):

Voltage at 100% SOC – 600V

Pack Configuration – 140s1p

Simple & Durable

The goal of this design is to minimize mass, cost, and manufacturing complexity, all while fulfilling the rules set by the FSAE EV class.

With a fully 3D-printed nylon shell, the frame supporting the cells weighs a mere 0.5kg. This design also makes it possible to manufacture a completely ready-to-drive module in under 2 hours, where in previous years the process could take days, and sometimes weeks.

Each module is rated for an impact of up to 40G in the lateral axes and 20G vertically, with specific design features implemented in order to prioritize reliability and safety.

Another highlight of this design is its ease of serviceability. In the event of a cell failure, a new cell can be hot-swapped into an existing segment in under 20 minutes if quick onsite maintenance is required.

Cooling-Free Thermal Model

A challenge with high-discharge applications of batteries is the immense amount of heat produced, where heat increases exponentially with current. This makes it imperative to have a thermal management strategy to ensure the integrity of the cells and safety of the pack.

The pouch cells that our team chose for this pack have a measured internal resistance (DCIR) of 1.5mOhm, which gives us the flexibility to employ a special thermal strategy that removes the need for any active cooling system, greatly reducing mass and the footprint of the overall pack

Using real-world data from on-track testing and competition runs, I’ve developed a method to profile transient current draw in such a way that quantifies the heat generated. This allows us to predict pack temperature after certain events, and gives us the necessary information to precondition our battery pack accordingly.

Maximized Reliability

In the endurance run at Formula Hybrid and Electric in 2023, our battery pack failed due to a disconnected spot weld in the cell-to-cell interconnect. Due to the overwhelming number of individual spot welds within the pack, we were unable to pre-emptively diagnose the issue.

In this design, the cell-to-cell interconnects are mechanically fastened, rather than reliant on a spot weld. This allows us to have absolute confidence in the integrity of each connection between cells. We are also able to repair individual connections between cells, which is invaluable for on-track servicing of modules.

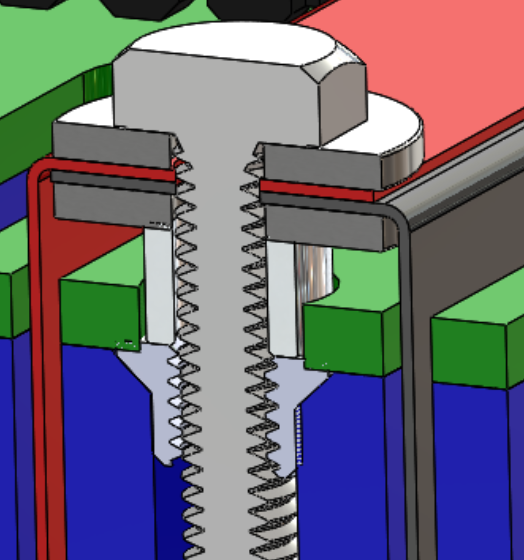

A cross section of the bolted stackup between each cell is shown to the right. A bolt is placed through the positive and negative tabs of two adjacent cells, with hardware to facilitate proper clamping of the tabs for consistent conductivity, and an aluminum spacer to keep the tabs at a constant height. The bolt is also driven into a special jetnut with deformed threads, which retains the bolt and resists loosening from vibrations while driving.

Cell Validation Before Installation

Material and Component Prep

Material and Component Prep

3 Bases of Segments Assembled and Labeled

50V on the First Manufactured Segment

All 10 Modules After Assembly

Side View of Finished Segment

Top View of Finished Segment

Full Pack